How To Put Glass In A Window

How to Glaze a Window (Unmarried Pane)

Tighten upward drafty old windows with new glazing putty

Every editorial product is independently selected, though we may be compensated or receive an affiliate committee if you purchase something through our links. Ratings and prices are authentic and items are in stock as of fourth dimension of publication.

![]() Time

Time

A full day

![]() Complexity

Complexity

Beginner

![]() Cost

Cost

Less than $20

Introduction

Single pane windows can last for a hundred years or more if properly maintained. Learn how to preserve your windows and go on them draft-gratis by replacing old glazing putty.

Tools Required

Materials Required

- Acrylic caulk

- Glazing points

- Glazing putty (oil or latex)

- Window glass (if necessary)

On older single-pane windows, the drinking glass is usually surrounded past putty called "glazing chemical compound," which holds the glass in identify and seals out the weather. This putty oft lasts decades, only over the years information technology becomes rock-hard, cracks and even falls off the window. Loose or missing compound lets wind and rain leak in around the drinking glass.

Replacing the putty around ane pane of drinking glass will take 15 minutes to an 60 minutes, depending on the size of the pane and the stubbornness of the old putty. Replace broken glass while you're at it. This adds only a few minutes and a few dollars to the job—much cheaper than calling a drinking glass repair service.

It's possible to replace drinking glass and putty with the window in place, just you lot'll salvage time and become better results if y'all tin remove the window and clamp it downwardly on a flat surface.

If you have broken glass, get information technology out of the way before you lot remove the old putty. Put on heavy gloves and eye protection, identify a cloth over the cleaved pane and tap it with a hammer. With the glass thoroughly cleaved up, pull the shards out of the frame past hand. Pull out the old glazing points with pliers. If the old glass is in good shape, leave information technology in place. Plus, learn how to wash your windows the fastest way with crystal clear, streak-free results.

Project step-by-step (7)

Step 1

Remove the old window glaze putty

The next step is to get rid of the old putty. If the putty is badly cracked, you tin can pry away large chunks quickly with a putty pocketknife.

Putty in skilful condition takes longer to remove. With a heat gun in 1 hand and a stiff putty pocketknife in the other, heat the putty to soften it and gouge it out. Article of clothing leather gloves to protect your hands from burns. Keep the heat gun moving to avoid concentrating heat in 1 spot. Otherwise, the heat will crevice the glass.

If your estrus gun doesn't have a heat shield attachment, protect the glass with a scrap of sheet metallic. When the putty is removed, prime any blank wood within the window frame. A shellac-based primer such every bit BIN is a good choice because it dries in minutes.

Step two

Erstwhile window panes: Supersede the glass and putty the window

If you need new drinking glass, measure out the opening, decrease 1/8 in. from your measurements and accept the new drinking glass cut to size at a full-service hardware store. Have a shard of the old drinking glass with you to match the thickness.

Too, buy a package of glazing points to hold the drinking glass in identify while the new chemical compound hardens. Glazing compound is available in oil-based and latex/acrylic versions.

The latex products, which commonly come up in a tube, take a longer life expectancy and you don't accept to look days before painting them equally you lot exercise with oil-based putty. But they often begin to dry before you lot tin can tool them polish. If neat, polish results are of import, choose an oil-based putty.

Step three

Sometime window panes: Ready the glass in place

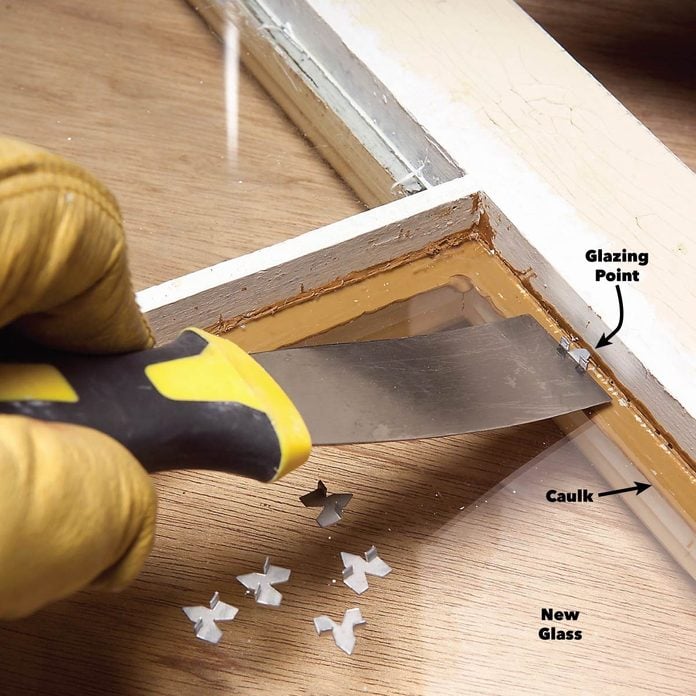

For installation of new glass, the directions on glazing chemical compound may tell you to lay a light bead of the chemical compound inside the frame and and then gear up the glass over it. That works well with soft latex chemical compound. Just if y'all're using stiffer oil-based compound, lay in a light bead of acrylic latex caulk instead. Prepare the drinking glass onto the caulk, then wiggle and press down to firmly embed the drinking glass.

Press glazing points into the wood every 8 in. Let the backlog caulk that oozes out under the glass harden and piece it off with a utility knife later.

Step iv

One-time window panes: Spread the compound

Comprehend the perimeter of the glass with a heavy layer of chemical compound. Be sure to completely fill in the recess; don't leave any gaps or hollow spots.

Step 5

One-time window panes: Polish the compound

To consummate the chore, smoothen out the new glazing compound. Dip a putty knife in mineral spirits to lubricate information technology and shine out the compound. Wet the knife over again and run over the compound as many times every bit it takes to create a smooth surface.

Oil-based putty is easier to piece of work with when it's warm. To heat it, set the can in a bowl of hot water for a few minutes. Remember that oil-based putty remains soft for days, and then be careful non to impact it subsequently smoothing. Yous'll have to wait several days before you can prime number and pigment oil-based putty; check the label.

Pace six

One-time window panes: Clean the excess

Drag the ridge of backlog chemical compound away from the finished articulation and scrape it up. Be careful not to impact the smoothed surface.

Step 7

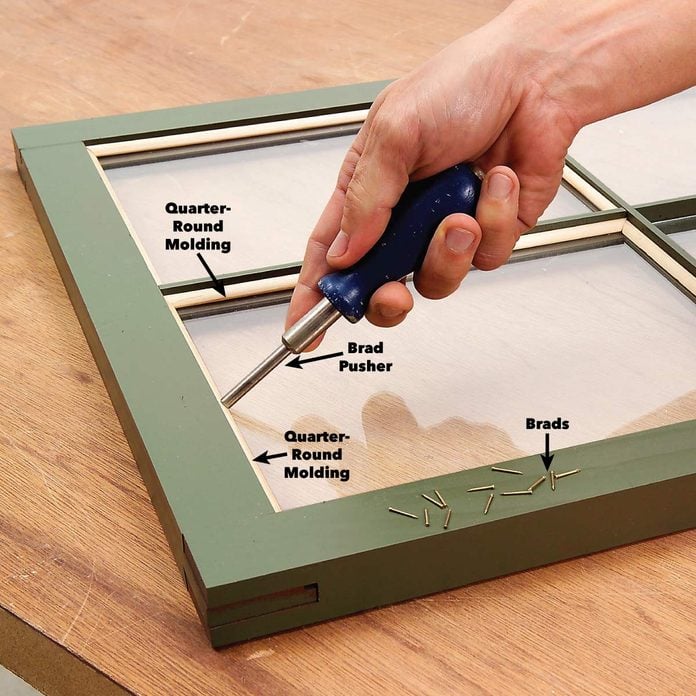

An alternative to putty: Mitered moldings

Applying a smoothen, perfect dewdrop of window glazing compound is fussy, time-consuming work. Then when good looks matter, consider woods moldings rather than putty to concur the drinking glass in place (1/4-in. quarter round works for nigh windows).

Set up the drinking glass in place over a lite bead of latex caulk. At that place'due south no need for glazing points. To nail the moldings in identify, y'all can carefully drive in tiny brads with a hammer or carefully shoot in brads with a pneumatic brad nailer.

But the safest method is to utilize a brad pusher. A brad pusher is simply a metallic tube with a sliding piston inside. Drop a brad in the tube, button hard on the handle, and the piston pushes the brad neatly into the wood—with little danger of breaking the glass. Most hardware stores and dwelling centers don't carry brad pushers, but you can find them at woodworker supply stores or online.

Go a brad pusher on Amazon.

Originally Published: August 27, 2019

Source: https://www.familyhandyman.com/project/how-to-glaze-a-window-single-pane/

Posted by: smithsuand1943.blogspot.com

0 Response to "How To Put Glass In A Window"

Post a Comment